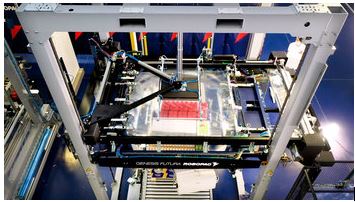

Automatic stretch wrapping machine with rotating ring GENESIS FUTURA - HS

Description:

A wide range of rotating ring machines to wrap and stabilise loads on pallets with stretch film designed for multiple merchandise sectors.

The Genesis Futura series wrapping machines, like Genesis HS series machines, operate without sliding electrical contacts and feature the exclusive system that powers prestretch driven units with batteries charged during machine pauses at pallet infeed and outfeed. This technical and highly innovative solution, in addition to eliminating all the typical problems of sliding contacts, also significantly reduces the overall machine weight and correctly balances rotating masses. All this, in addition to guaranteeing reduced investment costs and, consequently, high competition levels, ensures: low electrical energy consumption; reduced maintenance; high reliability and long working life.

The modularity of the structural and functional units provide high flexibility and versatility expressed with traditional pallet models.

Types of wrapping machines:

|

|

|

|

FUTURA HS |

FUTURA 2 |

Key features:

| FUTURA HS | FUTURA 2 | |

| Min-max pallet dimensions (mm) | 400x600 - 1220x1220 | 400x600 - 1220x1220 |

| Max pallet height (mm) | 500 - 2000; | |

| Output capacity (paleti/h) | 110; - T.I.* | 125; - T.I.* |

| Pre-stretch carriage | SCF std.; SCV / SVC-P opt. | |

| Power supply voltage (V) | 400-415 ± 5% | |

| Power supply frequency (Hz) | 50 ± 1% | |

| Air pressure (bar) | 6± 1 | |

| Air consumption (Nl/min) | 250; 350 T.I. | |

| Reel height (mm) | 500 std. 750 opt. | |

| Max reel diameter (mm) | 250 | |

| Film thickness workable (µm) | 17 - 30 | |

| TOP Film thickness (µm) | 40 - 100 | |

* T.I. - With top sheet applicator.

Options:

Pre-stretch carriages:

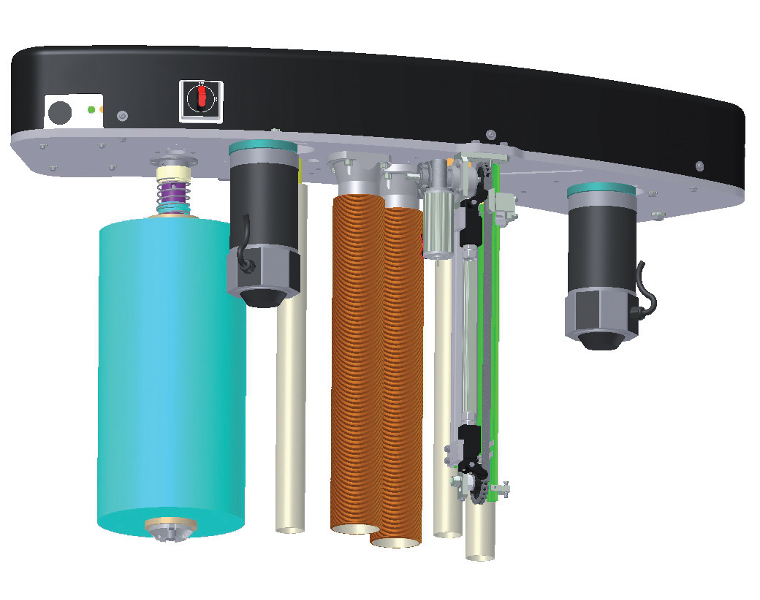

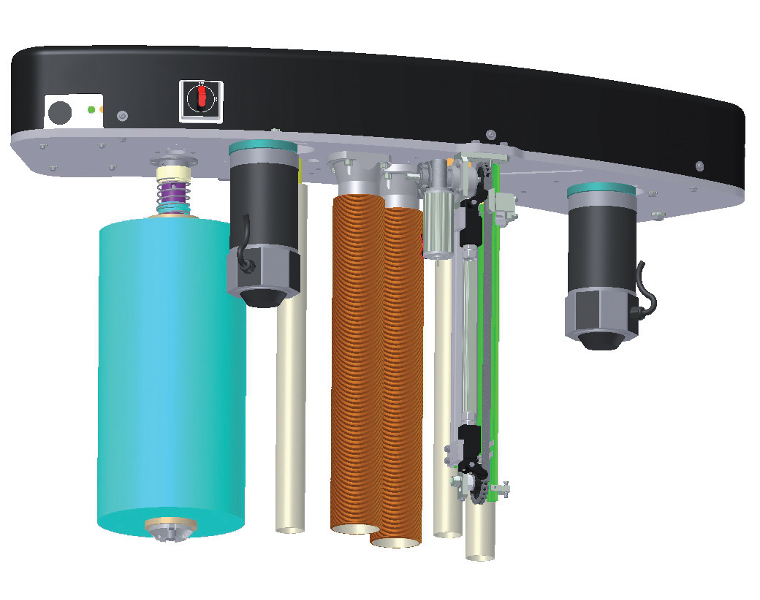

|

|

| SCV | SCV-P |

- SCF - Two carriages with single motorization on-board of each one, powered through electrical sliding contatcs. Possibility to pre-stretch the film at fixed values up to 350%.

- SCV - Pre-stretch carriage with double independent DC motorisation on-board, with electric current generator and ultra-capacitors. Variable pre-stretching with 150%-400% range. Cube technology level 1.

- SRV P - Pre-stretch carriage with double independent DC motorisation on-board, with electric current generator and ultra-capacitors. Variable pre-stretching with 150%-400% range. Cube technology level 2.

|

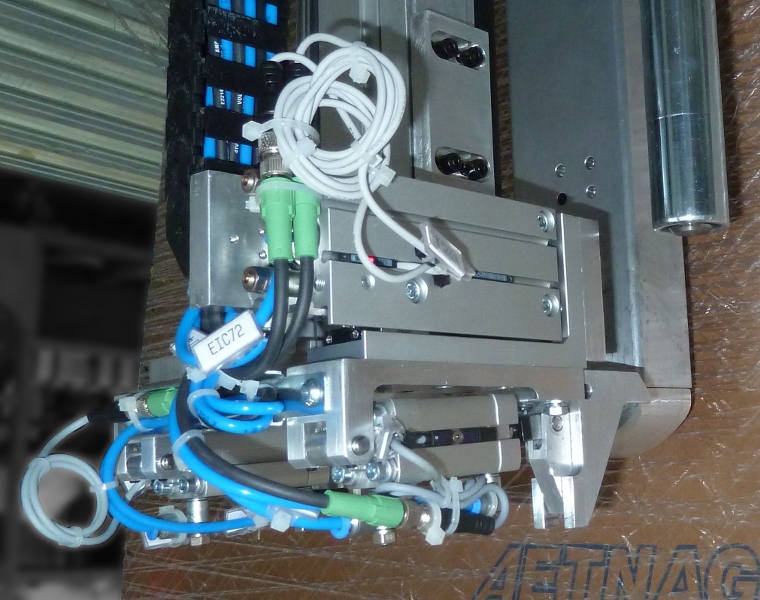

|

| Integrated system with cutting and welding | Clamp with wrapping film tail insertion |

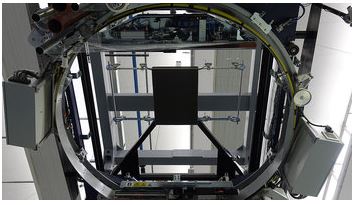

Others:

|

|

|

| Pressure platen | Pallet lifter | Top cover |

|

|

|

| Roping | Corner applicator | Arc reel-change |

Video: