Loading...

EVO - Fully automatic blowing machines

Stratos 10:

EVO 10 is a 2-cavity, fully automatic electric machine dedicated for production of PET bottles for production of PET bottles 3,0l – 12,0l with capacity up to 3 000 bph for 5L.

Key features:

- Capacity: 3 000bph for 5L and 2500 bph for 10l, pressure of high blow 20-35 bar

- Advanced PLC control with a user-friendly interface allows easy regulation of the system of stretching and heating preforms

- Chain system for preforms transport through the oven – hot preforms are taken from the transport chain by the manipulator and moved to the closing unit manipulator, which transport them directly to the blowing moulds. Loading of heated preforms and collecting of ready bottles take place simultaneously in one move of the manipulator.

- Ready oriented bottles are placed on plate or air conveyor

- Useful equipment as standard :air recuperation system, central lubrication system, internet module- quick help and support for customer, UPS system which protects PLC and motion controllers of the machine , POWER WIZARD™ – solution designed to ensure a stable temperature for the preforms during the reheating process.

- Optionally available Power Stabilizer for servo drives or/and oven section and preform dumper – preforms are loaded into a preform hopper automatically

- Using the best materials & components: MITSUBISHI, NORGREN, SKF, WENGLOR, ALLEN-BRADLEY, SICK, INA

EVO 20:

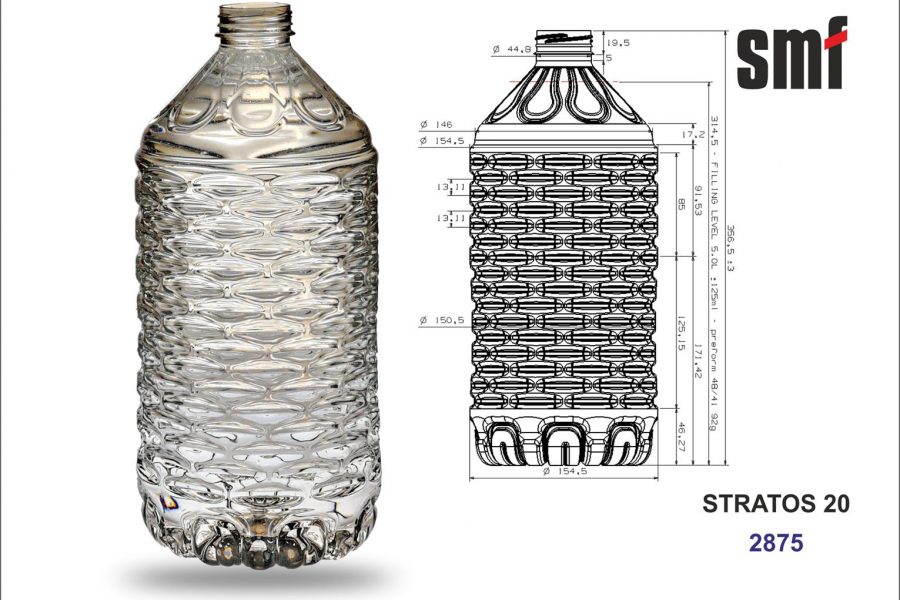

EVO 20 is a 1-cavity, fully automatic, electric machine dedicated for production of PET bottles for production of PET bottles 5,0l – 20,0l with capacity up to 600 bph for 20l. On this machine, it is also possible to produce 5Gallon reusable bottles (BPA free) using 700gr preforms, optionally also with the plastic handle.

Key features:

- Capacity:600bph for 20 5L, pressure of high blow 35 bar

- Advanced PLC control with a user-friendly interface allows easy regulation of the system of stretching and heating preforms

- Chain system for preforms transport through the oven – hot preforms are taken from the transport chain by the manipulator and moved to the closing unit manipulator, which transport them directly to the blowing moulds. Loading of heated preforms and collecting of ready bottles take place simultaneously in one move of the manipulator.

- Ready bottles are placed on plate or air conveyor

- Useful equipment as standard :air recuperation system, central lubrication system, internet module – quick help and support for customer, UPS system which protects PLC and motion controllers of the machine , POWER WIZARD™ – solution designed to ensure a stable temperature for the preforms during the reheating process.

- Optionally available Power Stabilizer for servo drives or/and oven section and preform dumper – preforms are loaded into a preform hopper automatically

- Using the best materials & components: MITSUBISHI, NORGREN, SKF, WENGLOR, ALLEN-BRADLEY, SICK, INA