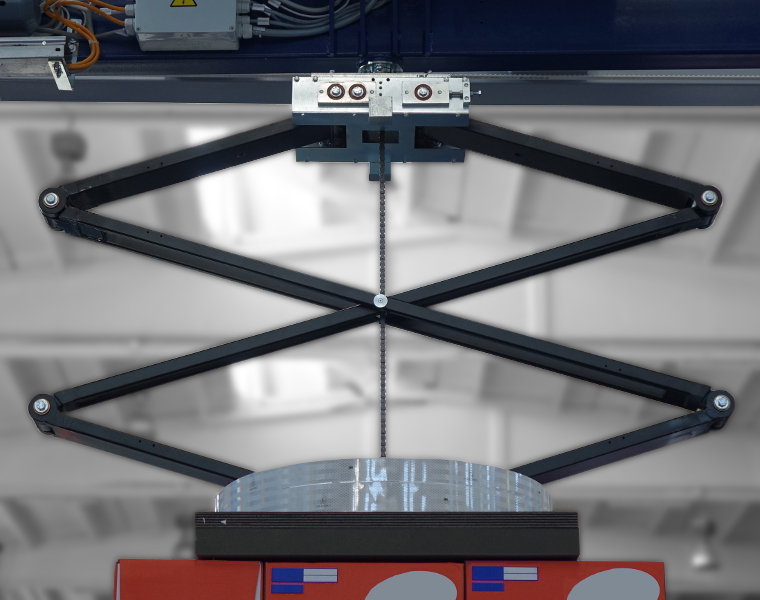

Automatic wrapping machine with rotating arm Helix

Description:

A complete range of automatic machines with rotating arm for stretch wrapping of palletized loads particularly indicated in those fields where high production outputs are required. Thanks to the rotating arm technology, film deposit and load stabilization occur on fixed pallet hence eliminating any load falling risk regardless the arm rotation speed. The machines of the Helix series represent the ideal solution for wrapping light, easily deformable, unstable loads and find vast application in the most various market segment fields.

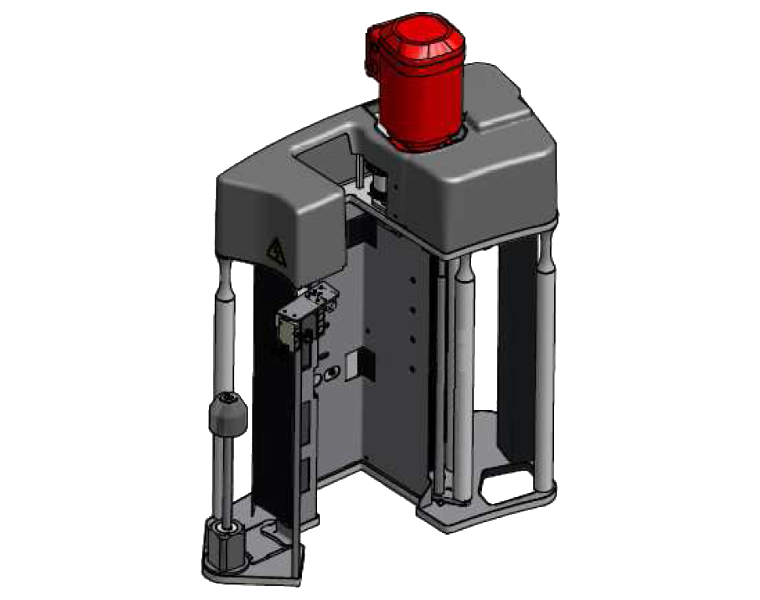

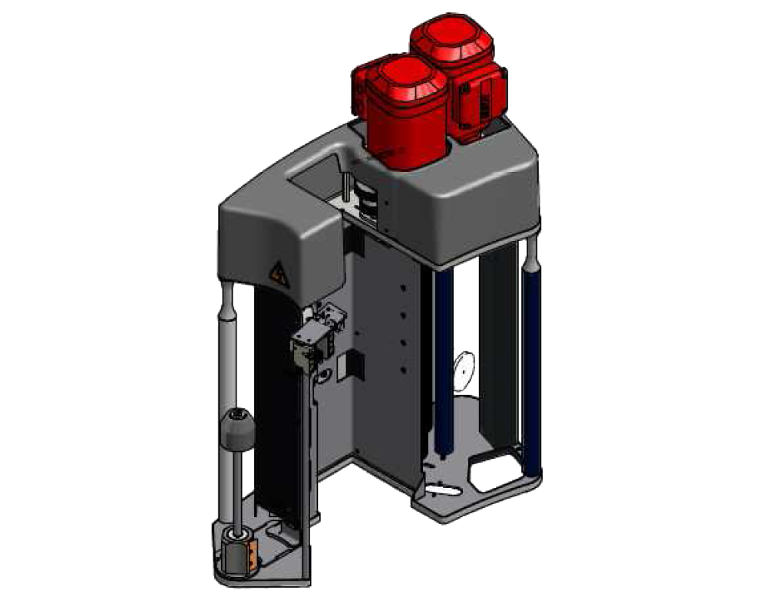

The modularity of the units that compose them allows an ample versatility of use even when large dimensioned loads are present. Such versatility is translated into 3 models with individual arm and 1 model with double arm.

Types of wrapping machines:

|

|

|

|

|

Helix 1 EVO |

Helix 3 EVO |

Helix 4 EVO |

|

|

|

|

Helix 4/2 |

Helix MAX |

Key features:

| Helix 1 | Helix 3 | Helix 4 | Helix MAX | Helix 4/2 | |

| Min-max pallet dimensions (mm) | 400x600 / 1220x1220; 1600x1600 vers. Helix 4 L; 1900x1900 vers. Helix 4 XL | 600x800 / 1000x1350 | |||

| Max pallet height (mm) | 2000 | ||||

| Output capacity (paleti/h) | 65* | 80* | 90* | 105* | 150* |

| Pre-stretch carriage | PGSM / PGSA / SCSP / SCSP/2 | ||||

| Power supply voltage (V) | 380 -400 -415 ± 5% | ||||

| Power supply frequency (Hz) | 50 | ||||

| Air pressure (bar) | 6 | ||||

| Reel height (mm) | 500 std. 750 opt. | 2x500 | 500 std. 750 opt. | ||

| Max reel diameter (mm) | 250 | 250 std. 380 opt. | 250 | 250 std. 380 opt. | |

| Film thickness workable (µm) | 17 - 30 | ||||

| TOP Film thickness (µm) | 40 - 100 | ||||

* Output capacity without Top Sheet applicator.

Options:

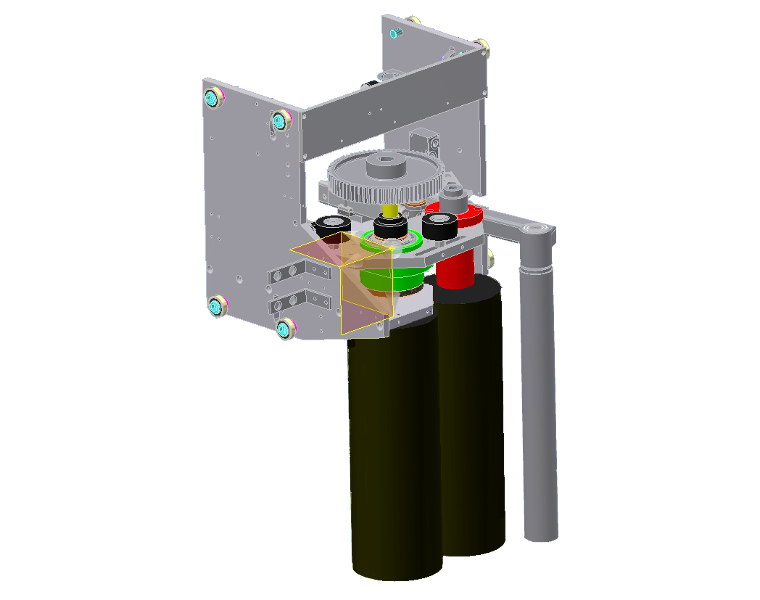

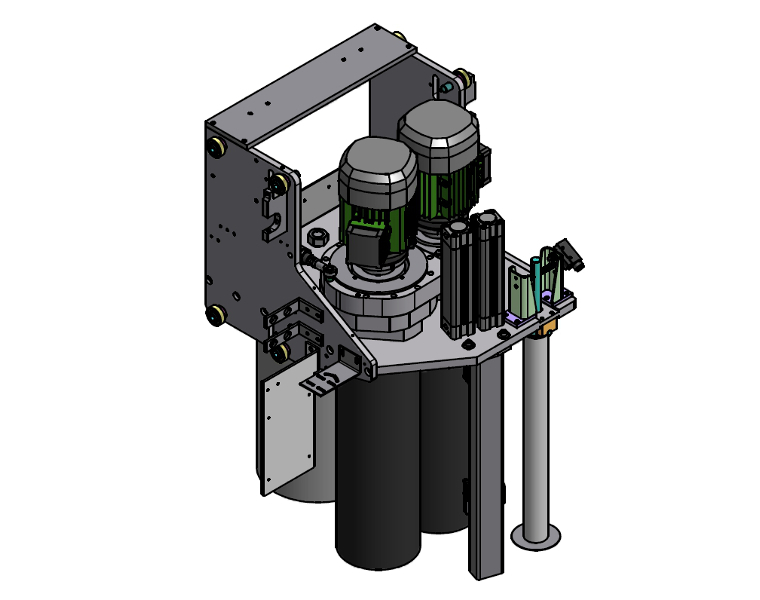

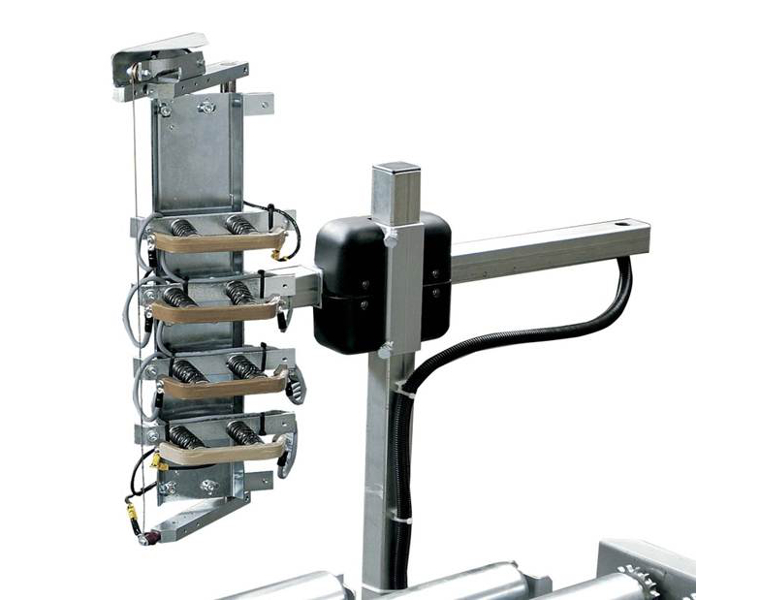

Pre-stretch carriages:

|

|

|

|

| PGSM | PGSA | SCSP | SCSP/2 |

- PGSM - Pre-stretch carriage with single motorisation, which allows the stretch film to be pulled at fixed values up to 350%.

- PGSA - Pre-stretch carriage with double independent motorisation, which allows to pre-stretch the film from the control panel, with a 100%-400% range.

- SCSP - Pre-stretch carriage with single motorisation, which allows the stretch film to be pulled at fixed values up to 300%.

- SCSP/2 - Pre-stretch carriage with double motorisation SSC independent, which allows the stretch film to be pre-stretched from the control panel, with a 150% -400% range

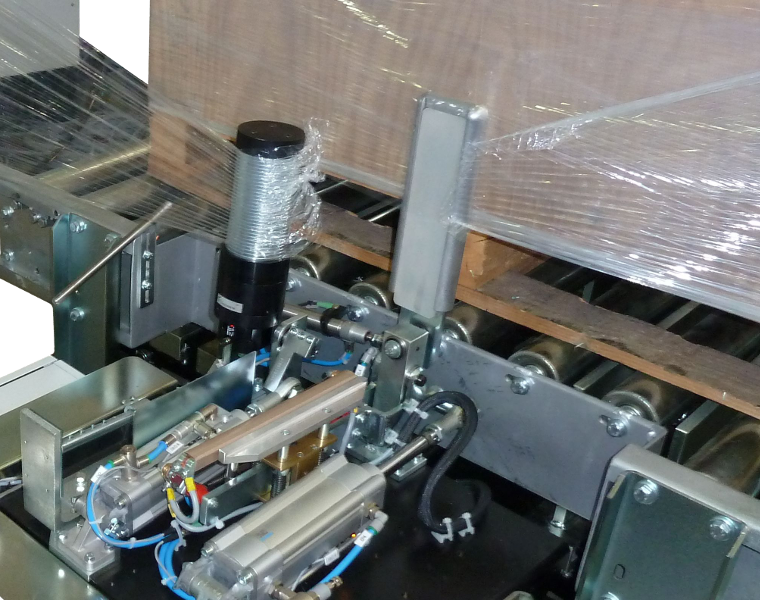

Clamps cut and seal the film at the end of the wrapping:

|

|

|

| System to obtain perfect sealing of the stretch film | Which occurs without contact with the product | Wrapping film is inserted into the winding itself |

Others:

|

|

|

|

|

| Pressure platen | Pallet lifter | Top cover | Roping | Corner applicator |

Video:

Helix 3 EVO:

Helix 4 EVO:

Helix Max:

Helix 4/2: