Loading...

Semi-automatic random size boxes taping machines

Description:

Adhesive sealing machines for cardboard boxes. The machine no need to be set manually for the dimensions of each box but it adjusts automatically.

It is recommended for companies with a wide range of box types, where working in similar batches is not possible.

Closing the box flaps must be done by a human operator until after the box is taken over by the sealing machine.

From the point of view of the technology used, the equipment is divided into two categories:

|

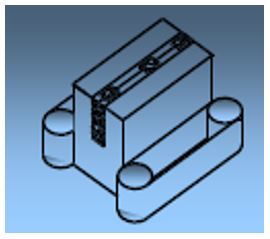

- those with conveyor belts located on the side: |

Robotape TBDA

|

|

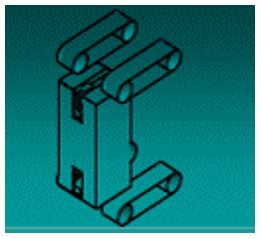

- those with conveyor belts located up and down: |

Robotape A HD

|

Technical Features:

| TBDA | A HD | |

|

Height conveyor belt (mm) |

50 | 50 std. 75-115 opt. (65 A) / 115 std. 75 opt. (80 A) |

| Infeed speed (m/min) | 22 | 22 |

| Tape width (mm) | 50 (50 TBDA W=135 mm) 50-75 (50 TBDA W=160 mm) / 50-75 (65 TBDA) | 38/44/50 - 75 |

| Film flag (mm) | 50 - 70 | 50 - 70 |

| N. 2 taping units | opt. | opt. |

| Min. box Dim. (LxWxH) (mm) | 150x135x110 (50 TBDA W=135 mm) 150x160x110 (50 TBDA W=160 mm) / 150x160x110 (65 TBDA) | 150 x 110 (T50)/135 (T75) x 110 (B=50) std./135 (B=75) opt./175 (B=115) opt. |

| Max. box Dim. (LxWxH) (mm) | ∞x500x500* (50 TBDA) / ∞x650x650* (65 TBDA) | ∞ x 650 x 650 (65 A) / ∞ x 800 x 800 (80 A) |

| Box min. weight (kg) | 1 | 1 |

| Box max. weight (kg) | 50 | 50 |

| Power supply voltage (V) | 400V 3Ph + T | 400 V 3Ph+N+T 50 Hz |

| Power supply frequency (Hz) | 50 | 50 |

| Installed power (kW) | 0,4 | 0,5 |

| H machine (mm) | 1810 (50TBDA); 1960 (65TBDA) | 1972 |

| W machine (mm) | 890 (50TBDA); 1040 (65TBDA) | 1291 |

| L machine (mm) | 1433 | 1062 |

| Weight machine (kg) | 162 (50TBDA); 184(50TBDA) | |

| Working height (mm) | 670-850 | 670-850 |

| Air consumption (Nl/min) | 158 (50 TBDA) 218 (65 TBDA) | 142 (65 A HD); 164 (80 A HD) |

| Working pressure (bar) | 6±1 | 5 |