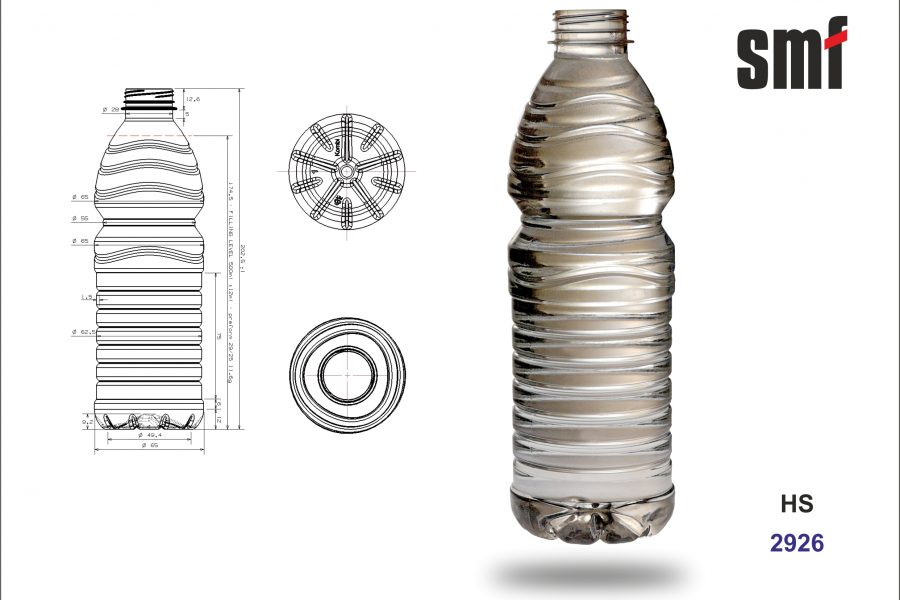

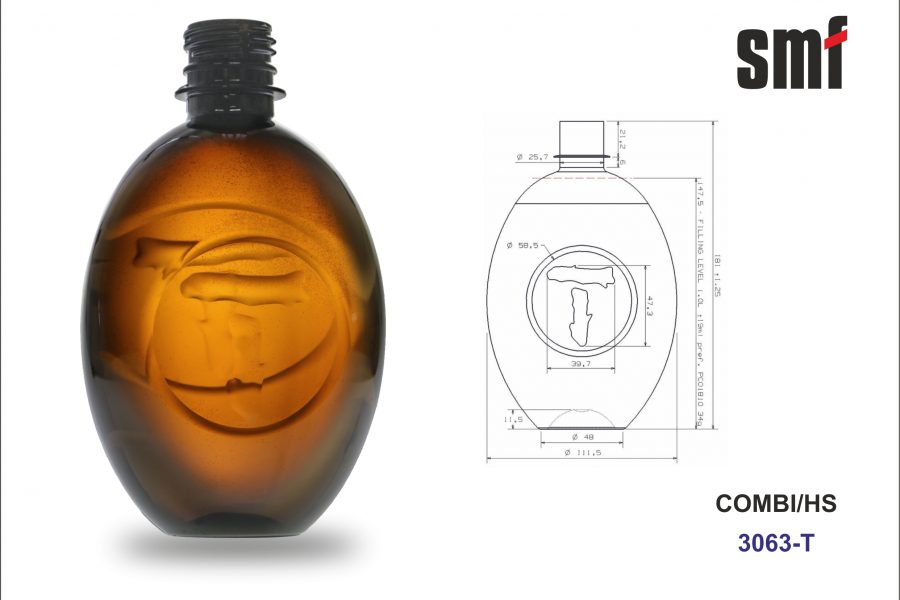

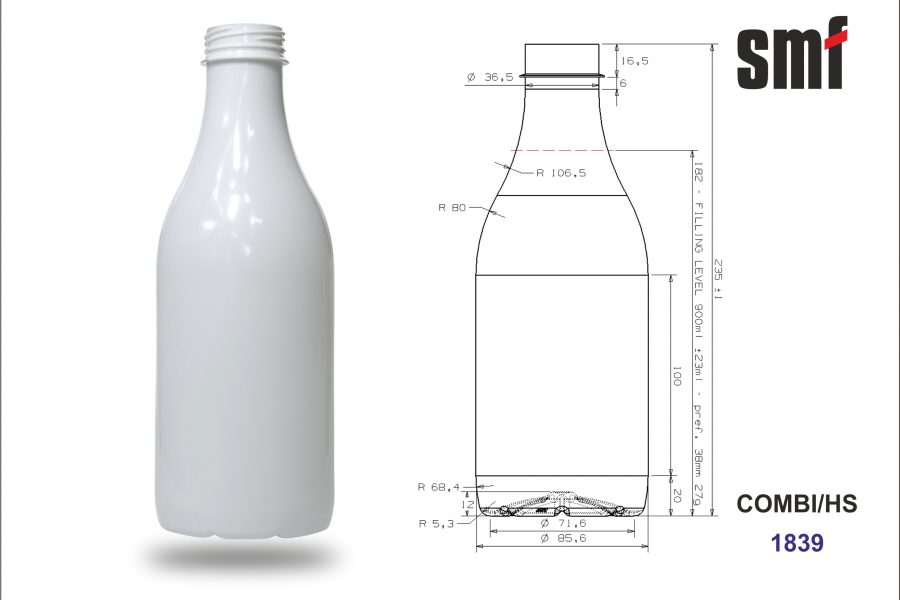

Series HS - Fully automatic blowing machines from 0,2 to 3 L

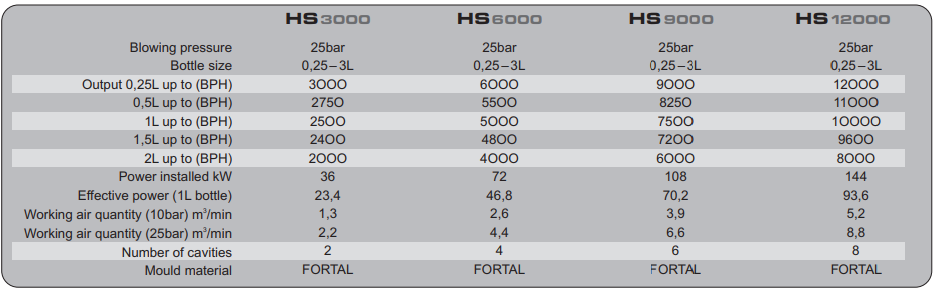

The HS series includes 4 machines:

HS 3000 - is a 2-cavity, automatic blow moulding machine designed for production of PET bottles 100ml- 2500ml ( optional up to 3000ml), with capacity 3000bph for 500ml.

HS 6000 - is a 4-cavity, linear, automatic blow moulding machine with nominal working speed of 6000bhp of 500ml. HS can produce bottles from 200ml up to 2,5l ( optional- up to 3l )

HS 9000 - is a 6-cavity, linear, automatic blow moulding machine with nominal working speed of 9000bhp of 500ml. HS can produce bottles from 200ml up to 2,5l ( optional- up to 3l )

HS 1200 - is a 8-cavity, linear, automatic blow moulding machine with nominal working speed of 12000bph of 500ml. HS can produce bottles from 200ml up to 2,5l ( optional – up to 3l ).

All main operations such as preform loading, movements of the closing unit and strech rods are made by FESTO pneumatic cylinders.

Preform transport system is based on special disigned pins suitable for different neck types like water, carbonated soft drinks, oil or chemical preforms.

Modular construction allows to combine machine secions together in one frame ( HS3000 to HS 12000). HS machines can work separately or in the line with SMF bottle unscramblers.

Key features: